DIFFERENT NOW: Plates 2025

As a designer there should be a response to a material, whatever material that's chosen, instead of dictating it. It creates a stronger relationship between the designer, the object, and the user.

Starting with an Aluminum sheet, a line, and I began to press and allow the metal to draw in an uncontrollable fashion. This strengthened the metal and gave form, then the corners were rolled to meet the table. Throughout all ideations, each side of the object was measured and drawn by hand, and began to layer them in drawing and photographs.

There was a change in material and the idea of a press and wrinkle was translated to slip cast ceramic, a process that ensured control and a product that can be replicated. Ceramic also meets the table, food, and spoon more delicately, something that is important when dining.

Sketches of the water jet cut and press mark

Drawing sent to the water cut cutter

Water jet cut

Putting a layer of carbon onto sheet

Burning the carbon off, finishing the annealing process

Pressing the sheet

Rolling the corner

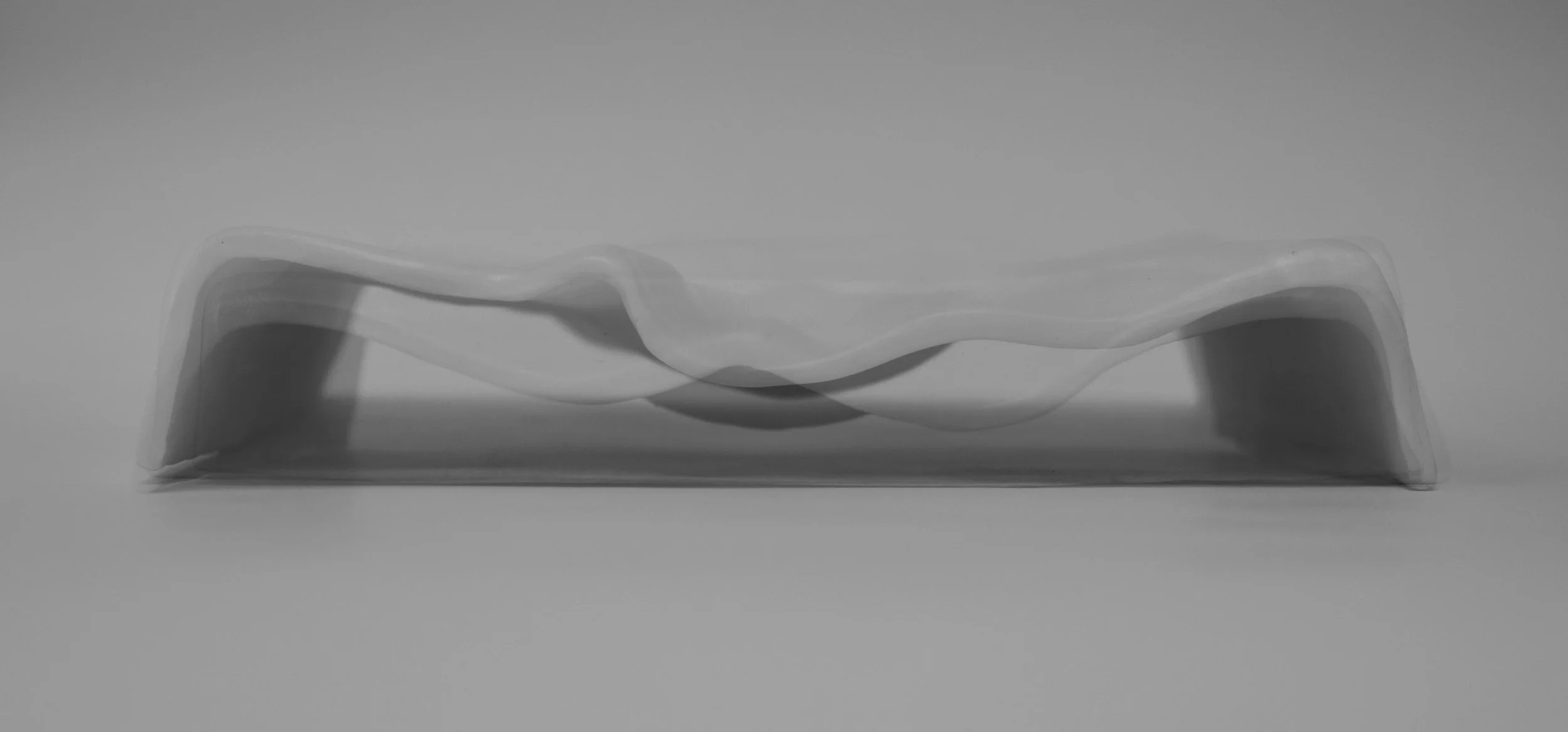

Final Form

Drawing VS Plate

Detail

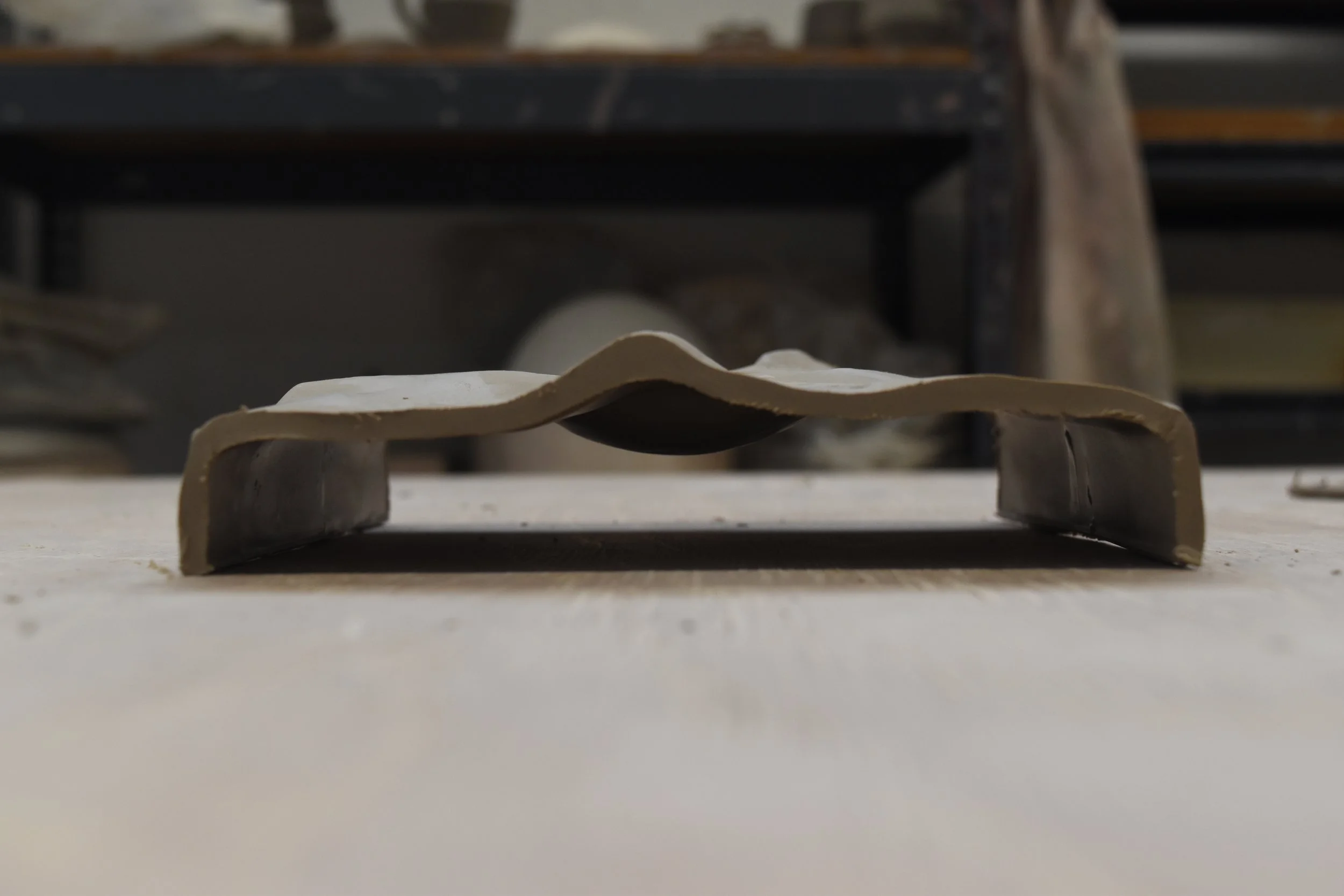

Carving the ceramic positive

Slip casting

Side profile of greenware

See DIFFERENT NOW: MEMÒRIES D’ESPANYA VEGETALS for the process of the food